Always safe

Reduced activity

High value

Very high cost reduction

Low-carbon

Carbon footprint reduction

Innovative Concept

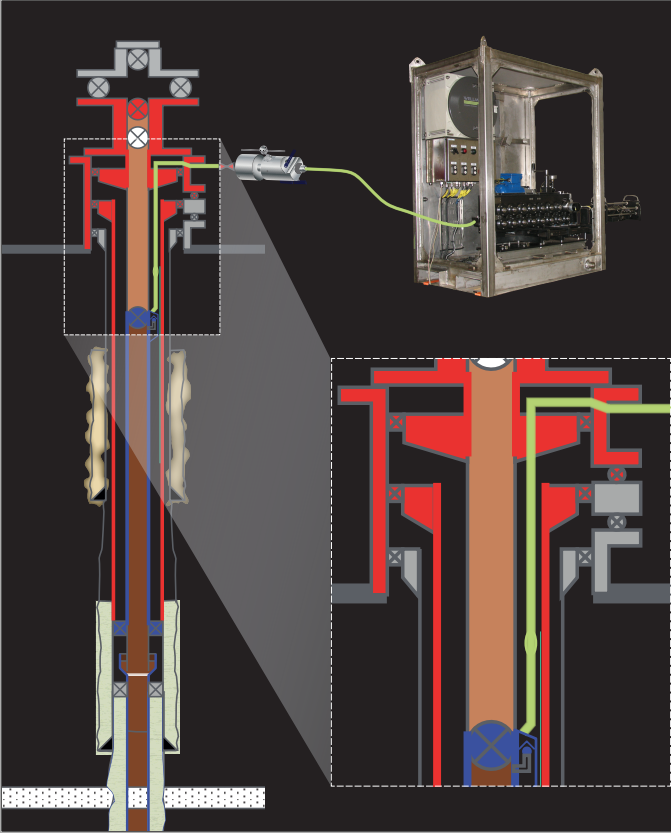

WellMend is an innovative concept witch offers inspection, repair and rectification of safety valve control line problems rather than replacing the entire safety valve through a workover operation.

Our solution is to repair the control line - through intervention.

Solution features

Offers inspection, repair and rectification of safety valve control line problems.

OUR SOLUTION

WellMend NanoCoil solution is an innovative service that offers inspection, repair and rectification of safety valve control line problems rather than replacing the entire production tubing. This prevent long and costly periods of down time which in turn would lead to significantly reduced repair cost and increased production efficiency for the oil companies and in turn lower lifting cost per barrel produced. Reduced downtime and repair cost for safety valves with faulty control lines represent the main challenges that this WellMend NanoCoil solution provide. The hydraulic control line tubing typically has an inner diameter of 3.6 mm, the tubing length ranges from 200 to several hundred meters, and several bends in the tubing create restrictions. Chemicals used to mend leakages have high viscosity, and the tooling pipe must be able to transport such chemicals even though the inner diameter is very small, typically 1,5-2mm. Potential customers for this service are oil and gas companies that operates in areas with regulations that require functional safety valves in order to produce hydrocarbons. The WellMend NanoCoil solution have been well received among the operators we have dialog with.

Proudly presents a control-line repair solution.

Replace pressure block without wireline intervention.

We take pride in delivering only the best. We're a service company born out of a passion for making great solutions. When a control line failure is reported this leads to a shut-in of the production due to loss of a barrier. The normal response is that well intervention is called on and are attempting to fix the control line from the tubing side. If this fail the well is listed or work-over and would then have to compete with drilling of new wells or P&A work. With a solution that does not rely on access to the drilling rig this would bring the well back in production much faster.

Start fixing control line with WellMend.